Showing posts with label Process safety and security. Show all posts

Showing posts with label Process safety and security. Show all posts

February 26, 2022

The Benefits of Explosion-Protected Cameras in High-Risk Environments

The Benefits of Explosion-Protected Cameras in High-Risk Environments: Many critical infrastructure sites contain areas that are classified as hazardous due to a high risk of explosion. What makes most of these locations

February 18, 2022

Cybersecurity: The Biggest Threats Are Likely Within Your Organization

Cybersecurity: The Biggest Threats Are Likely Within Your Organization: Cybersecurity: The Biggest Threats Are Likely Within Your Organization

February 14, 2022

The Urgency of Protecting the Electric Grid from Cyberattacks

The Urgency of Protecting the Electric Grid from Cyberattacks: The Urgency of Protecting the Electric Grid from Cyberattacks

September 26, 2021

March 27, 2018

November 28, 2014

USB sticks and security issues

In 2012, two power plants in the USA were affected by malware attacks, brought in by USB sticks. Read the article in this link.

Have you banned USB sticks in your plant?

Contribute to the surviving victims of Bhopal by buying my book "Practical Process Safety Management"

Have you banned USB sticks in your plant?

Contribute to the surviving victims of Bhopal by buying my book "Practical Process Safety Management"

December 7, 2013

Changes proposed to OSHA PSM rule

"On Dec 3, 2013 The U.S. Department of Labor's Occupational Safety and Health Administration announced a request for information seeking public comment on potential revisions to its Process Safety Management standard and related standards, as well as other policy options to prevent major chemical incidents. The RFI is in response to executive order 13650, which seeks to improve chemical facility safety and security, issued in the wake of the April 2013 West, Texas, tragedy that killed 15 in an ammonium nitrate explosion. Once the RFI is published in the Federal Register, interested parties may submit comments online atwww.regulations.gov, by mail or facsimile. To view the RFI visithttp://www.osha.gov/chemicalexecutiveorder/OSHA_PSM_RFI.pdf. For more information, visitwww.osha.gov/chemicalexecutiveorder/index.html."

Contribute to the surviving victims of Bhopal by buying my book "Practical Process Safety Management"

Contribute to the surviving victims of Bhopal by buying my book "Practical Process Safety Management"

August 11, 2011

Process safety and security - facility siting

A news article mentions the presence of a warehouse containing ammonium nitrate near refineries and fertilizer plants in Visakhapatnam. Recently, the Govt. of India has recently brought Ammonium Nitrate under the explosives act after its usage by terrorists.

The article mentions the following:

"At the time of setting up of this facility in 2007, there was a furore. After the environment assessment report was presented before the MoEF (ministry of environment and forests), the matter went for public hearing, which saw many local residents protesting storage of this hazardous substance, backed by some political parties as well. "But like in many other cases, public objection was overlooked and the government cleared the project, which is again illegally built on the CRZ (costal regulation zone) area," said Mr Sarma.

"Vishakhapatnam is a busy and an important area," he added, "it is a major Coromandel port, it houses the headquarters of the Eastern Naval Command, is an ecologically sensitive zone and is an industrial and commercial hub. Several incidents—from the 26/11 massacre to the sinking of MV Rak—have shown us how vulnerable our coastlines are. In such a situation, storage of explosive substances like ammonium nitrate is a big risk, especially when there are no checks on it."

Read the article in this link.

The article mentions the following:

"At the time of setting up of this facility in 2007, there was a furore. After the environment assessment report was presented before the MoEF (ministry of environment and forests), the matter went for public hearing, which saw many local residents protesting storage of this hazardous substance, backed by some political parties as well. "But like in many other cases, public objection was overlooked and the government cleared the project, which is again illegally built on the CRZ (costal regulation zone) area," said Mr Sarma.

"Vishakhapatnam is a busy and an important area," he added, "it is a major Coromandel port, it houses the headquarters of the Eastern Naval Command, is an ecologically sensitive zone and is an industrial and commercial hub. Several incidents—from the 26/11 massacre to the sinking of MV Rak—have shown us how vulnerable our coastlines are. In such a situation, storage of explosive substances like ammonium nitrate is a big risk, especially when there are no checks on it."

Read the article in this link.

December 8, 2010

Chemical Terrorism and mock drills

The department of homeland security in the US has recently conducted a mock drill for a terror attack induced scenario. The scenario was three simultaneous accidents - ammonia leak from rail tanker, sulphuric acid leak from rail tankers and a train derailment with chlorine tankers.

In India, though we do have a Chemical Accidents (emergency planning, preparedness and response) rules, 1996, we have a long way to go before we are truly prepared for what the US is already prepared.

Read the article about the mock drill in this link.

In India, though we do have a Chemical Accidents (emergency planning, preparedness and response) rules, 1996, we have a long way to go before we are truly prepared for what the US is already prepared.

Read the article about the mock drill in this link.

October 24, 2010

A third eye for process safety

After the BP oil rig disaster, authorities in the US are now planning to monitor the critical parameters of all oil rigs from land. An article mentions that the system will "put real-time data from offshore wells in front of government-employed petroleum engineers, who could keep a close watch during vital drilling operations or whenever anomalies are detected.Many drilling contractors and oil companies already use high-tech monitoring systems to keep track of what's happening offshore -- even from computer centers hundreds of miles inland".

Now while this is a good idea, it throws up another window regarding security of such networks. Just imagine if someone was able to unauthorizedly break into these networks!

I personally feel that while technology can be an enabler,it cannot solve all problems. Read the full article in this link.

Now while this is a good idea, it throws up another window regarding security of such networks. Just imagine if someone was able to unauthorizedly break into these networks!

I personally feel that while technology can be an enabler,it cannot solve all problems. Read the full article in this link.

October 14, 2010

Process safety and the Stuxnet worm

A news article mentions the following: "A sophisticated worm designed to steal industrial secrets and disrupt operations has infected at least 14 plants, according to Siemens.Called Stuxnet, the worm was discovered in July when researchers at VirusBlokAda found it on computers in Iran. It is one of the most sophisticated and unusual pieces of malicious software ever created -- the worm leveraged a previously unknown Windows vulnerability (now patched) that allowed it to spread from computer to computer, typically via USB sticks.

The worm, designed to attack Siemens industrial control systems, has not spread widely. However, it has affected a number of Siemens plants, according to company spokesman Simon Wieland. "We detected the virus in the SCADA [supervisory control and data acquisition] systems of 14 plants in operation but without any malfunction of process and production and without any damage," he said in an e-mail message".

As technologies become more and more complicated, chemical plants are also becoming susceptible to attack through the software and other technologies they use. Do not be complacent about your plant software security systems. Many chemical companies ban USB sticks inside their premises.

Read more of the article in this link.

The worm, designed to attack Siemens industrial control systems, has not spread widely. However, it has affected a number of Siemens plants, according to company spokesman Simon Wieland. "We detected the virus in the SCADA [supervisory control and data acquisition] systems of 14 plants in operation but without any malfunction of process and production and without any damage," he said in an e-mail message".

As technologies become more and more complicated, chemical plants are also becoming susceptible to attack through the software and other technologies they use. Do not be complacent about your plant software security systems. Many chemical companies ban USB sticks inside their premises.

Read more of the article in this link.

April 30, 2010

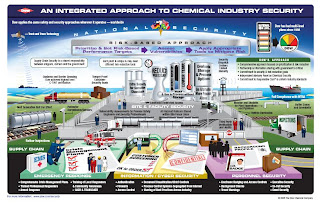

Process safety and security

Dow Chemicals has beautifully pictured their "integrated approach to chemical security management" on their website in this link

I wonder when India will really wake up to chemical security threats and bring in legislation and enforce it. With the threats of naxalites and external terrorists and the fact that a number of hazardous chemical units are based on the coast,it becomes imperative that a coordinated approach to chemical plant security is implemented. Let us not wait for an attack to happen!

January 23, 2010

Emergency response to terror threats

Terrorism has brought about an added dimension to Process Safety Management. Recently an article mentioned that terrorists may target Indian refineries. Is your organization prepared to handle terror threats? The starting point for determining weak links in your security is by conducting a security vulnerability assessment. Do not assume your current security framework can take care of such threats. Also, prepare an emergency response plan in case the worst takes place. How are you maintaining your emergency isolation valves to shut off feed to the plant and to isolate affected sections? How good are your flare and venting systems protected against collapse during a major fire? How quickly can you safely shut off your plant and evacuate personnel? These are some of the questions that need to be answered.

December 31, 2009

Process safety and security

A couple of days back an ULFA activist was caught near a oil refinery in Assam with lots of explosives. This was reported in the newspapers. Process safety and security are interlinked. The US formed the department of homeland security after 9/11. They look also at security of vulnerable chemical sites in the USA. India too should look into the security of chemical plants. We should learn from the experiences of others.

Subscribe to:

Posts (Atom)